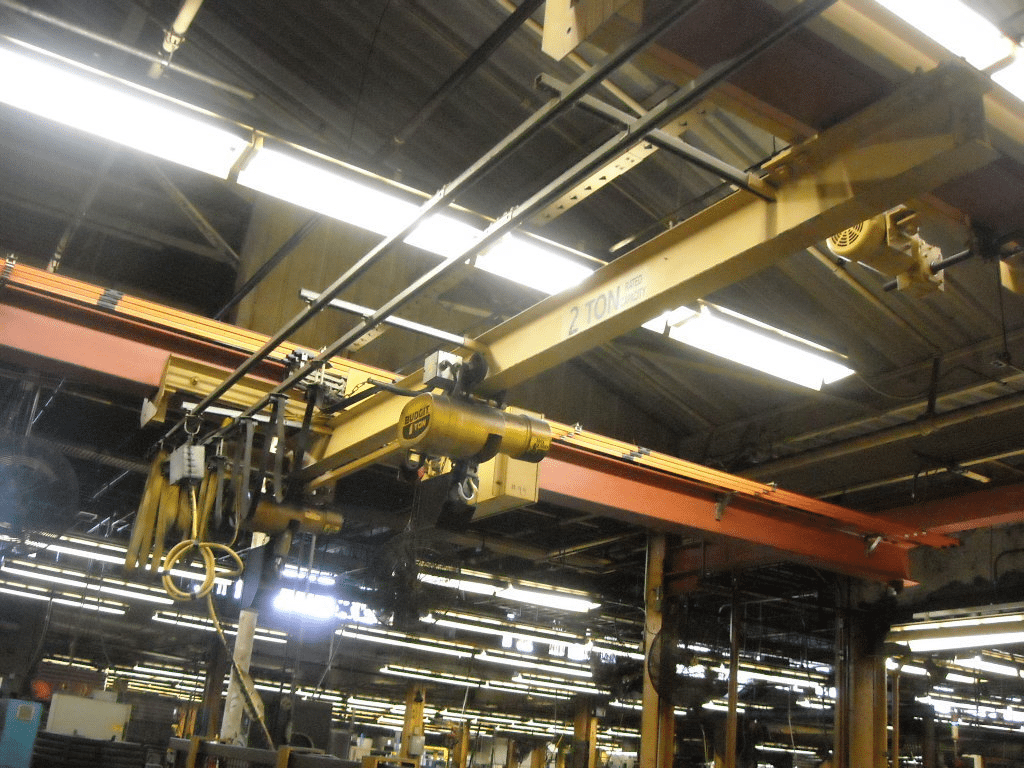

Operating a Workstation Crane as well as Every little thing Involved with It

Cranes are unquestionably valuable in the work atmosphere. They could lift large amounts of weight in addition to make jobs faster along with even more reliable. However, due to their huge power they are also extremely harmful. If a load goes down there is almost no chance to stop it neither alert other workers to move out of the way. The resulting damage can result in major injury in addition to a fatality. The majority of crane crashes entail human mistake, so the right prep work along with training is important. By learning the very best methods to function Cranes safety and security and also safety, feasible mishaps can be considerably stayed clear of.

Prior to running a workstation crane employees need to keep in mind of the crane's qualities including the crane's weight, is the hoist rope qualified for the load, are the loads obtaining attached appropriately? Recognizing this common details obtains the employee prepared to run the crane securely.

There are great deals of sorts of cranes however workstation cranes are one of one of the most efficient in addition to harmful form of crane in addition to the mental aspects of running a crane could not be ignored. 90% of Crane-related mishaps are triggered by human error so the very best mindset, initiative as well as fundamental knowledge are needed. An incident could eliminate you or somebody else, so the considerable nature of psychologically preparing yourself could not be overstated.

A great deal of crashes that occur are frommed bad judgment, lack of attention or overconfidence. Diminish a mental list prior to you begin. Ask yourself is you are literally along with mentally prepared to work with the tools. If you are taking drug ask your medical professional or pharmacologist if it might impact your efficiency. Also, ask yourself if you are mental ready. Are you crazy, dismayed and a lot more prone making rash decisions?

Preparing likewise consists of putting on safety garments as well as gadgets consisting of steel-toed safety footwears, a construction hat along with security glasses to assist shield versus dropping items. An embedded, long sleeve tee t shirt is furthermore needed.

When you are literally in addition to emotionally all established for the work you should evaluate the Crane and also the location where you will absolutely be functioning. Search for little leakages, clear the space away around the crane making certain workstation cranes that nothing is in the ways along with inspect the crane itself. Examine the fluid levels, steerings as well as likewise brakes while focusing for uncommon noises. Also, it's exceptionally important to inspect the Limitation Switches over that removed power at the end of a crane's variety of motion as well as the hook making sure it continues to be in exceptional functioning order as well as right for the job.

What Are the Benefits of a Trench Shoring System|Purchase Securely Online

Throughout excavation, a trench shoring system offers security for employees in a trench and then accelerate excavation. In this situation, trench shoring need to not be perplexed operating shielding. Trench shoring is developed to avoid collapse where protecting is only designed to safeguard employees when collapses occur. Concrete structures shoring, in this case also referred to as incorrect job, provides short-term assistance until the concrete becomes hard as well as achieves the preferred toughness to sustain loads. Trench shoring system entails the process of supporting the wall surfaces of a trench to stop collapse. The expression can also be made use of as a noun to describe the materials made use of in the process. Several methods can be made use of to support a trench. Hydraulic shoring is making use of hydraulic pistons that can be pumped external until they push up versus the trench wall surfaces. They are typically integrated operating steel plate or a special heavy plywood called Finform. An additional method is called beam and then plate, in which steel I-beams are driven into the ground and steel plates are glided in amongst them. A similar approach that uses wood slabs is called soldier boarding. Hydraulics tends to be faster as well as easier; the various other techniques have the tendency to be utilized for longer term applications or bigger excavations.

Trench boxes are technically checked top quality components for the optimal trench and then pipe laying jobs in depths between 1.25 meters as well as 6.0 meters. The differences in design as well as construction guarantee that the most suitable box is chosen and then allow efficient handling as well as unmatched economic output. The numerous compatible components, like spindles as well as struts as well as expansion bars make the use even much easier and then distribution as well as setting up as quick similar to nothing else box system. Rational thinking and then acting are the crucial debates for picking one of our box systems. Utilized hundreds of times on authorized building and construction sites certaining greatest use as well as highest adaptability.

Trench Box can manage any ground stress. With just a couple of parts-- panels, spindles, screws-- a trench boxes variety of economical means to shield trench excavations against collapsing throughout cable television jobs, pipe laying, manholes etc. in no time are possible. Trench box is utilized at more websites in more nations compared to other large location trench shoring devices in use today. Trench box is the optimum tool for mostly all dirt conditions as well as job demands where boxes are use-able. Base and also extension plates are produced in numerous sizes to satisfy all website problems. The sturdy reinforced top section and then strong reducing edge warranties lengthy life and then makes certain convenience of installment. This box offers both stamina as well as adaptability and makes collaborating with larger pipelines and then culverts feasible.

Get Overhead Cranes For Protection As Well as Prodactivity In The Production Shop

With device in hand and also a hefty object balancing on the work bench it may be an excellent concept to get the insurance coverage ready. If something drops or produces a hazard with a power tool the outcomes could be tragic. A hobby or professional task will certainly now set you back cash, time or life since of a missing out on but vital tool. Overhead cranes give another collection of hands and choices in the workshop. Resilient and also efficient in moving heavy things within a marked room with safety and security as well as efficiency while not being an impediment to a task schedule.

Regardless if it is at the job or an area established at home to play for enjoyable, crashes occur. Hefty training can create physical damages or a lawsuit if an onlooker is hurt. Go electrical and also further ease the concern of manually raising and also moving hefty objects around. Lifting a motor up at the end of a chain despite assistance is high-risk if an improvised gadget is used and also breaks or breaks your back instead. There are some things that must not be raised by unaided human stamina.

Relying on the location and sort of job to be done there is an appropriate selection offered. Usually thought about in dock work or steel mills where cargo or heavy steel is delivered a home garage or various other location take advantage of the exact same innovation. Beginning little and also broaden if what begun as a pastime ends up being a business or your small firm has broadened as well as needs much more devices compared to when originally set up. Benefit from added alternatives that were gone over when the design was made.

Metal light beams securely positioned with hoists as well as carts to move tools throughout a workshop, garage or various other location give the same integrity and versatility on a smaller sized range. With hoist capability objects are lifted from vehicle beds or other vehicle items as well as relocated throughout to a workbench or various other location in the shop.

Free standing cranesmake it possible for installment on a concrete floor to relieve the tension of being installed expenses and triggering possible weakening of building structure. Produce multiple bridges across beams and also permit separate job tasks to be carried out without waiting for cost-free time from an additional task.

Ceiling placed versions when floor space should be left open for relocating items or machinery. Mount securely when the framework of the building can accommodate the weight expected as well overhead cranes as will certainly not develop a safety and security threat listed below. Job with as well as obtain recommendations from the supplier to make sure that when carried out all safety and security inspections as well as functional training have actually been finished.

Whether aluminum or steel is picked the capacity to broaden design for added jobs is feasible. Even elaborate mazes could be developed for turning on a curve or changing alternatives to inspire the decision making feature into the total process.

Gain from ease of building as well as transportability from one location to one more. Use the several safety attributes and also recommendations to avoid an accident throughout setup and also usage. Have an instant increase in productivity as a result of the rate with which the units are set up.

What Are the Specifying Variables of a Shop Crane

Lifting, hoisting or lugging very heavy things by hand can have an unfavorable effect on the wellness of your workers. It is always suggested to use a shop crane to accomplish such activities in a brief time frame with minimal energy usage. Likewise referred to as a floor crane, this maker shows to be helpful to fields including however not limited to warehousing, material management facilities, production, automotives, building, welding, paint sector, garages as well as workshops. These cranes are a terrific financial investment since they last lengthy and save you unrivaled quantities of time and also power. If you frequently need to shift your crane from one place to another, you might select the foldable or portable crane.

Just what are the specifying elements of a shop crane?

The first point you have to take into consideration is the weight training abilities of the crane. Most of the times, a crane that is indicated for average use must have a weight training ability of 1,000 pounds. You could always pick a heavy responsibility crane design if you have to dealwith larger lots. The height of the crane matters also. A height of about 8 feet to 12 feet must suffice for routine lifting or lifting procedures on a shop flooring. Picking a workstation crane which lacks in height could leave you with poor results. The following most important specifications to think about are the performance as well as economic climate of the crane. Typically, you would need these cranes arounda shop flooring, garage, building website, storage facility or any various other center where you could should raise, lots, assemble and place heavy things. The crane should be able to bring tons efficiently and safely.

Furthermore, you may should take apart the crane periodically for transportation or storage. You ought to have the ability to perform these features in a fast as well as simple way. Regardless of exactly how bulky a shop crane is, quick and also problem-free disassembling plays a major part. There are certain crane ranges that could be dismantled in as much less as two mins. They could be developed into a small package that you can glide below cabinets or desks. Furthermore, ensure to check if the crane adheres to OSHA policies for risk-free office procedures. The security and also longevity of the crane is extremely important as well as it is secure not to have a lazy method to these variables.

If you need a mobile crane at, you can review your needs with a reliable manufacturer. In addition to a bridge crane, it is also advisable to purchase supplementary accessories and also accessories such as expansion booms, wide-legged wheelbase, narrow-legged wheelbase, manual winch cable lift, powered winch cable lift and so on. Nowadays a variety of makers have an on-line presenceComputer Modern technology Articles, which helps you search with their site and also products before making a last decision. The majority of leading makers likewise offer you the alternative of tailoring your shop crane in instance you do not locate your wanted bridge crane product in their typical offerings.

Trench Boxes Working at the Excavation | Purchase Directly Online Securely

Protect your excavation and underground utility contractors and your bottom line on the construction site with trench boxes. They are simple modular units which can be easily and quickly installed on the construction site by an excavator to provide strong, reliable shoring for most ground conditions whilst giving full protection for operatives in every stage of installation and removal. As workers dug trenches deeper, the sides of the trench had to be shored, or supported, to keep the walls of the trench from collapsing. All trenches have what is known as a stand-up time. The stand-up time is the time that elapses from the time the trench is dug until the trench walls start collapsing. Stand-up time is dependent on many factors, including soil type, water content, trench depth, weather conditions, and whether or not the soil has been previously disturbed.

When a construction project requires a large excavation, such as digging the foundation for a tall building, the support steel trench boxes structure for the excavated walls is specified in the plans. The main problem involving trench boxes occurs in cities, when water or sewer lines are being installed or repaired. The engineer usually does not specify the support structure for the trench on the plans, but leaves that to the contractor. The use of trench boxes on construction site will help to prevent trench failures from injuring workers. A trench box consists of two large plates, usually made of steel, which are parallel to the walls of the trench, and horizontal cross-members which hold the two plates apart. The lower edge of the box rests on the bottom of the trench, and the top edge extends above the top of the trench. The workers stay between the plates of the trench box, so that if the wall of the trench collapses, the dirt will be stopped by the trench box. As work progresses, the trench box is pulled along the trench with a backhoe.

Strong enough to keep trench workers safe from injuries or unstable soil, yet lightweight for easy transportation and assembly, aluminum trench boxes, are ideal for smaller jobs in place of steel trench boxes. Also known as trench shields, aluminum trench boxes are engineered to offer the protection and security for excavation that steel trench boxes provide, but are less than half of the weight while working on the construction site. They are customarily constructed with sidewalls of varying thicknesses held apart by steel or aluminum spreaders. Spreaders can be interchanged to match the width of the trench. The different materials and building designs lead to a variety of depth ratings, i.e. the depth of a trench that the shield can withstand a collapse without buckling. Depth ratings are determined by registered professional engineers.